-

NEWS CENTER

NEWS CENTER -

Contact Us

Contact Us

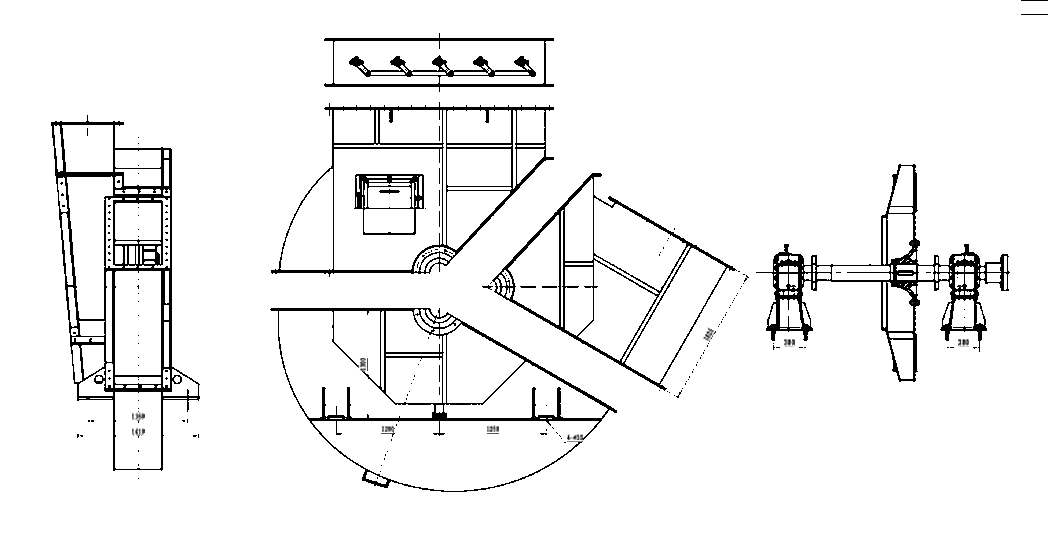

Model: 6-29 centrifugal fan

Machine No.: 2.8#~30#

Air volume: 52395-575176㎥/h

Wind pressure: 2304-140687Pa

Power: 5.5kw-2500kW

Uses: an induced draft fan that is often used in large-scale dust removal systems and industrial waste gas desulfurization and denitrification

Form: №2.8-6A adopts motor direct drive, №6-12C adopts pulley transmission, №6-12D adopts coupling transmission, №20-30F adopts cantilever support, and the impeller is between the two bearings. When the above models cannot meet your needs, we have the ability to design according to your needs.

Details description

6-29 series products have the characteristics of high efficiency, flat performance curve, wear resistance, working stability, etc.; excellent performance, can output high pressure, and can be used to transport non-flammable gases and particles/powder/ Debris/fiber materials are commonly used in large-scale industrial systems such as large-scale dust removal systems, desulfurization and denitrification of industrial waste gas, large-scale industrial boiler systems, large-scale industrial rotary kiln/calcining kiln systems, and mineral powder sintering (sintering machine).

product structure

Features

●It can output high outlet pressure, and can work under high medium temperature, suitable for any industrial occasions that need

to transport high pressure & high temperature gas.

●Customized design according to customer performance requirements, and optimized by CFD technology, the energy consumption is

lower than similar models.

●Material of impeller and main shaft, we will choose to use high-strength carbon steel, low-alloy steel, high-temperature-

resistant alloy steel, high-temperature-resistant high-strength alloy steel according to different medium temperature and

working speed, so that the impeller and main shaft can remain at high temperature Maintain reliable strength.

●For dusty gas, we can meet various working conditions from low dust content to extremely large dust content. After special

treatment, the surface hardness of the blade can reach HRC60~70, which can prolong the life of the impeller by more than 3

times.

●Appropriate joint surfaces of various components are closely matched, and the sealing performance is good to ensure that the

output pressure will not decrease.

●The impeller is annealed to completely eliminate the internal stress of the structure during welding to ensure that the impeller

will not have creepage and cracks.

●The welding seam of the impeller and the main shaft are ultrasonic flaw detection to ensure that there are no welding defects

and material defects, and the strength is guaranteed.

●The impeller is corrected by high standard dynamic balance to ensure the stable operation of the fan.

● Trial assembly after production is completed to ensure that there is no interference between components.

●Provide on-site arrangement guidance service.

Fan configuration

●Fan type: click direct connection, belt drive, coupling drive;

● Motor brands: Simma Motor, Lu'an Motor, Wannan Motor, Siemens and other well-known brands at home and abroad (can be

specified);

● Impeller: high-quality carbon steel, stainless steel, rubber lining, wear-resistant layer or wear-resistant lining plate,

ceramic patch (can be specified);

● Bearing: SKF, FAG, Wafangdian, NSK (can be specified);

● Spindle: high-strength carbon steel, combined with steel

●Bearing seat: cast iron

●Optional configuration: ※Integral bracket; ※Protective cover; ※Muffler; ※Inlet and export compensator; ※Hydraulic

coupling;※Motor rain cover;※Temperature sensor;※Vibration sensor;※Soft start device;※Inverter;

Hotline:0373-5827689 / 13603935651

Email:xmfjyxb@163.com

Address:China ● No. 343, Xima Avenue, Fengquan District, Xinxiang City, Henan Province

Copyright © 2021-2022 Xinxiang Simo Blower Co., Ltd. Henan ICP No. 19025136-2 SITEXML