-

NEWS CENTER

NEWS CENTER -

Contact Us

Contact Us

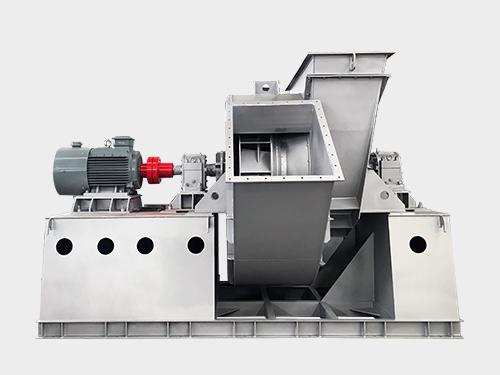

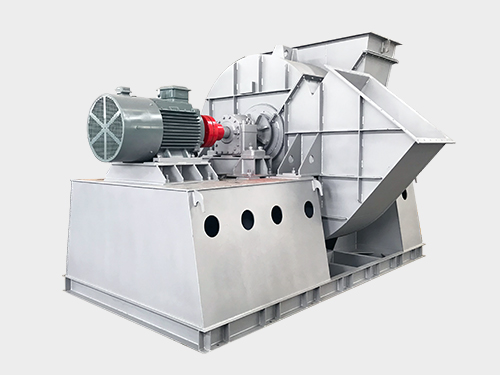

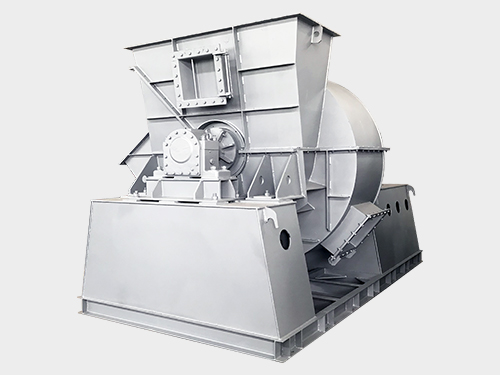

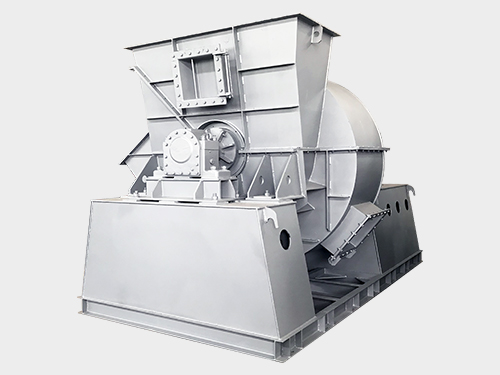

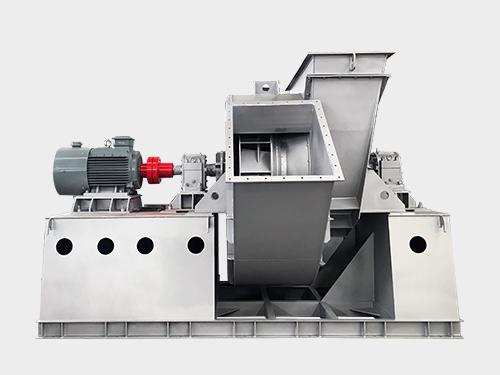

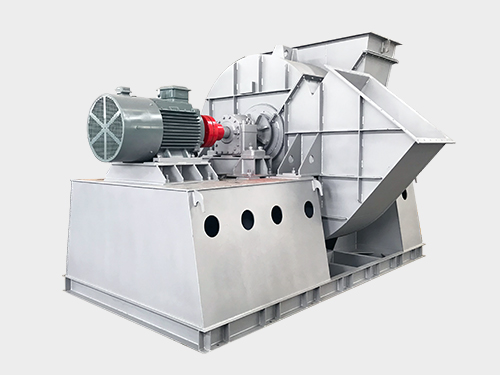

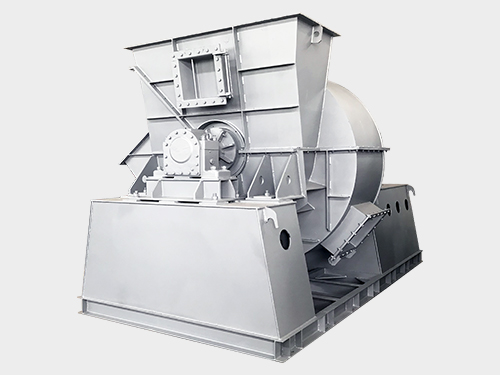

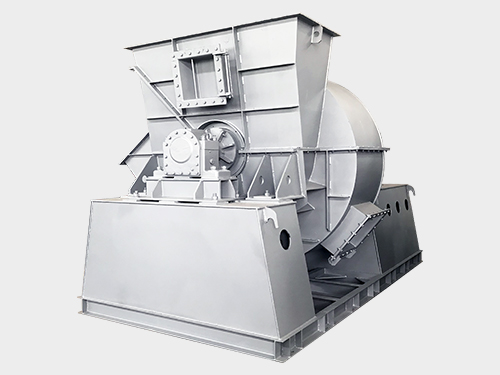

The 4-2X73 series is mainly used for large-scale induced draft and dust removal systems in metallurgy, electric power, cement and other industries. Due to the development of production, the boiler capacity has increased, the volume of the steelmaking furnace has also increased, and the amount of flue gas in the smelting process is also increasing. The air pollution is serious. With the increasingly perfect and strict environmental protection regulations, the smoke and dust must be purified. Therefore, the dust removal fan is designed to be large-scale with double suction, that is, with large flow, medium and high pressure, low noise, common cold and hot media, flat performance curve, high efficiency The characteristics of wide area, such as similar performance can also be used in other ventilation systems, but the medium temperature should not exceed 250 ℃. Before the induced draft fan, a dust removal device must be installed to ensure that the dust content in the flue gas entering the fan is minimized (generally not more than 200mg/m3). Impeller life.

1. The design of this series of fans is based on the aerodynamic sketches determined by the fan model test and adopts the technology of inclined cone air inlet, high-life backward impeller, anti-leakage bearing box, self-aligning and differential adjustment doors , Turning device (according to user needs) and other proprietary technical achievements.

2. The high-efficiency range is wide, and it is easy to select the high-efficiency working point.

3. The technology of the inclined cone air inlet eliminates the strong eddy current in front of the air inlet, ensures the stability of the air intake, and improves the overall efficiency of the fan

4. The impeller adopts rearward airfoil-shaped blades, which reduces the impact of airflow, has good stability, and the motor is not easy to be overloaded. and wear resistance, which prolongs the service life of the impeller.

5. The oil-leakage-proof bearing box adopts the lap-type oil slinger ring, which lifts the oil from the high-speed rotating bearing belt to the inner wall of the bearing box and flows back to the oil pool. The lower part of the labyrinth seal is provided with an oil return hole, so that part of the oil slinger ring is not filtered. The net oil is returned to the oil pool, and the outer skeleton oil seal can increase the resistance along the axial direction to intercept part of the thin oil back to the oil pool, and the dustproof performance is good. The upper part of the bearing box is provided with a vent plug, which reduces the slight positive pressure in the bearing box, and an oil level indicator is installed on the side of the bearing box, which can truly display the oil level. Sliding bearings can also be used according to user needs.

6. Self-aligning and differential-type adjusting doors, self-aligning bearings are provided at the fulcrum of guide vanes, and self-aligning linkage is adopted between the two sides of the adjusting doors. Due to the use of different angles of transmission handles, the opening of the blades during the adjustment process is improved. Different, realizes differential adjustment, smaller torsional torque, no "dead" point during operation and adjustment, flexible adjustment, labor-saving, safe and reliable, and ensures that the motor of the actuator is not overloaded

7. The fan is fully equipped, such as coupling cover, matching flange of the air inlet and outlet, anchor bolts of the whole machine, soft connection of the inlet and outlet, temperature measuring table (Pt100), vibration measuring device, if necessary, it can also be equipped with a slow-rotating device, Electric actuators or mufflers, etc.

8. Complete relevant parameters are provided, such as weight of main parts, static and dynamic load, rotor moment of inertia, adjustable door resistance torque and external dimensions, etc.

9. Key protection measures for product quality:

●Design and manufacture according to national and industry standards.

The performance of the fan is converted according to the model test

●The impeller and main shaft are subject to non-destructive testing according to the standard.

●Impeller adopts reinforced wear-resistant impeller

●The air inlet and outlet are provided with soft connection to prevent the interference of deformation stress between the pipe and the fan.

●The rotor adopts vibration protection device.

●A slow rotation device is used to prevent the bending of the stop shaft (when the temperature is high).

Hotline:0373-5827689 / 13603935651

Email:xmfjyxb@163.com

Address:China ● No. 343, Xima Avenue, Fengquan District, Xinxiang City, Henan Province

Copyright © 2021-2022 Xinxiang Simo Blower Co., Ltd. Henan ICP No. 19025136-2 SITEXML