-

NEWS CENTER

NEWS CENTER -

Contact Us

Contact Us

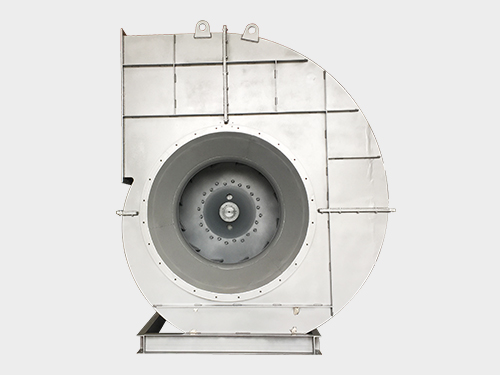

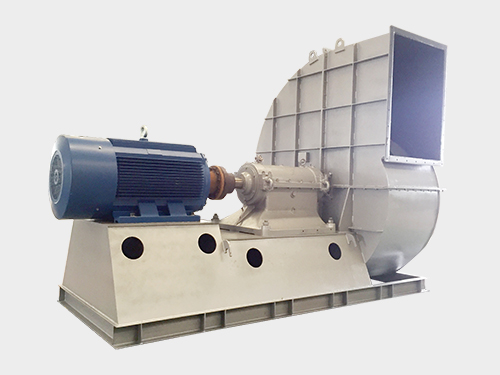

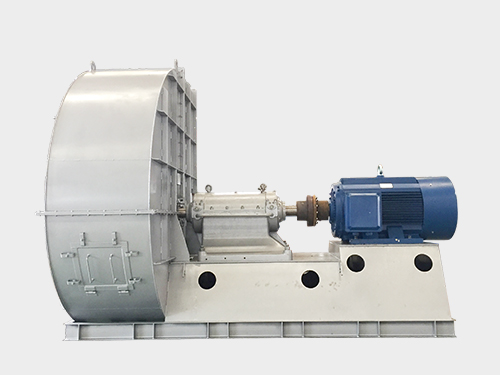

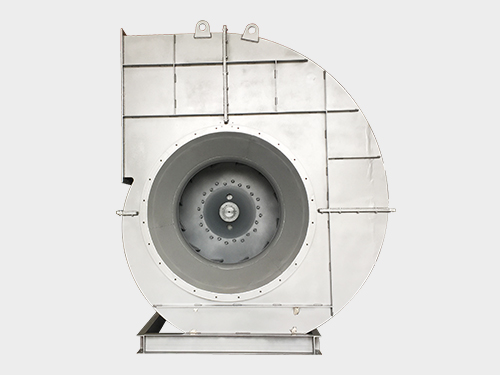

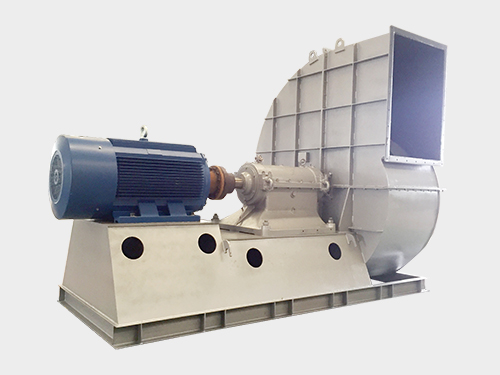

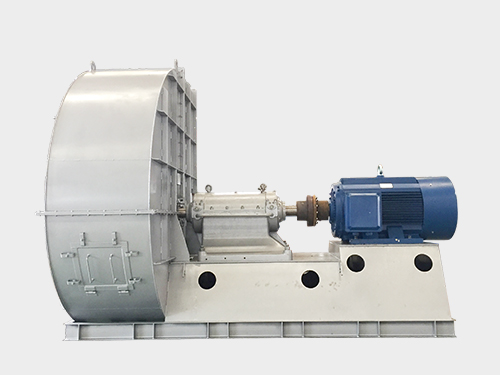

Model: G4-73 and Y4-73 boiler draft fan

Machine number: 8#~29#

Air volume: 10696-952530m3/h

Wind pressure: 615-8302Pa

Power: 5.5kw-1600kW

Uses: Mainly used for applications that require large air flow, low noise and high efficiency.

Form: The ventilator and the induced draft fan are made into single suction, and the machine numbers are №8D, 9D, 10D, 11D, 12D, 14D, 16D, 18D, 20D, 22D, 25D, 28D, 29.5D, a total of seventeen kinds, when the above machine No. can not meet your needs, we have the ability to design according to your needs.

working conditions

G4-73 and Y4-73 type ventilation and induced draft fans are suitable for ventilation and induced draft fan systems of 2-670T/h steam boilers in thermal power plants. It can also be used for mine ventilation and general ventilation when there are no other special requirements; it is mainly used for applications requiring large air flow, with low noise and high efficiency. It can transport clean gas, dusty gas, combustible gas, corrosive gas, powder or granular materials at room temperature or high temperature.

Application scenarios

Fume extraction, drying, clinker cooling, conveying gas, conveying light materials, blast and induced air for industrial boiler systems, supply and induced air for kiln systems / incinerator systems, air cleaning equipment, industrial dust collector systems In addition to the industrial field, it is also often used in the agricultural and civil fields, and is the most widely used fan series.

Fan structure

Features

●It can work stably at higher medium temperature, and can output a large gas flow and low noise when it meets the pressure requirements.

●The blade placement angle is optimized, which is more resistant to wear and has a longer service life.

●The pressure and flow of the fan can be flexibly adjusted during operation by using the regulating door. It can also be equipped with a variable frequency motor to adjust the pressure and flow of the fan by changing the speed.

●Material of impeller and main shaft, we will choose to use high-strength carbon steel, low-alloy steel, high-temperature-resistant alloy steel, high-temperature-resistant high-strength alloy steel according to different working conditions, temperature and working speed, so that the impeller and main shaft can withstand high temperature Reliable strength is still maintained.

●A fan system with a nominal impeller diameter of less than 1400mm running at room temperature does not need an additional bearing cooling device, which reduces the user's investment and maintenance workload.

●The impeller is annealed to eliminate the internal stress of the structure during welding, and to ensure that the impeller will not have creepage and cracks.

●The welding seam of the impeller and the main shaft are ultrasonic flaw detection to ensure that there are no welding defects and material defects, and the strength is guaranteed.

●The impeller is corrected by high standard dynamic balance to ensure the stable operation of the fan.

●There are a variety of optional accessories to choose from.

● Fan form: click direct connection, belt drive, coupling drive;

● Motor brands: Simma Motor, Lu'an Motor, Wannan Motor, Siemens and other well-known brands at home and abroad (can be specified);

● Impeller: high-quality carbon steel, stainless steel, rubber lining, wear-resistant layer or wear-resistant lining plate, ceramic patch (can be specified);

● Bearing: SKF, FAG, Wafangdian, NSK (can be specified);

● Spindle: high-strength carbon steel, combined with steel

●Bearing seat: cast iron

●Optional configuration: ※Integral bracket; ※Protective cover; ※Muffler; ※Inlet and export compensator; ※Hydraulic coupling;※Motor rain cover;※Temperature sensor;※Vibration sensor;※Soft start device;※Inverter;

Hotline:0373-5827689 / 13603935651

Email:xmfjyxb@163.com

Address:China ● No. 343, Xima Avenue, Fengquan District, Xinxiang City, Henan Province

Copyright © 2021-2022 Xinxiang Simo Blower Co., Ltd. Henan ICP No. 19025136-2 SITEXML