-

NEWS CENTER

NEWS CENTER -

Contact Us

Contact Us

Sima Fan can design and manufacture industrial centrifugal fans for various purposes according to customer needs

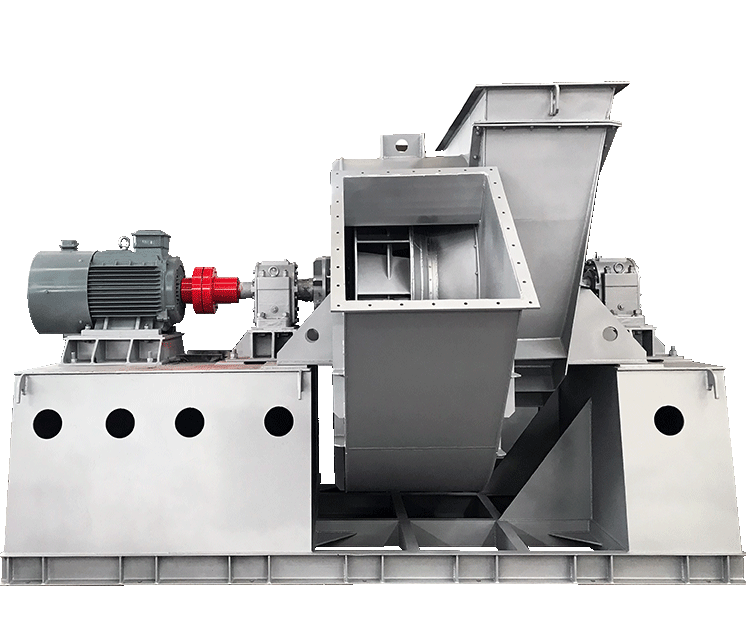

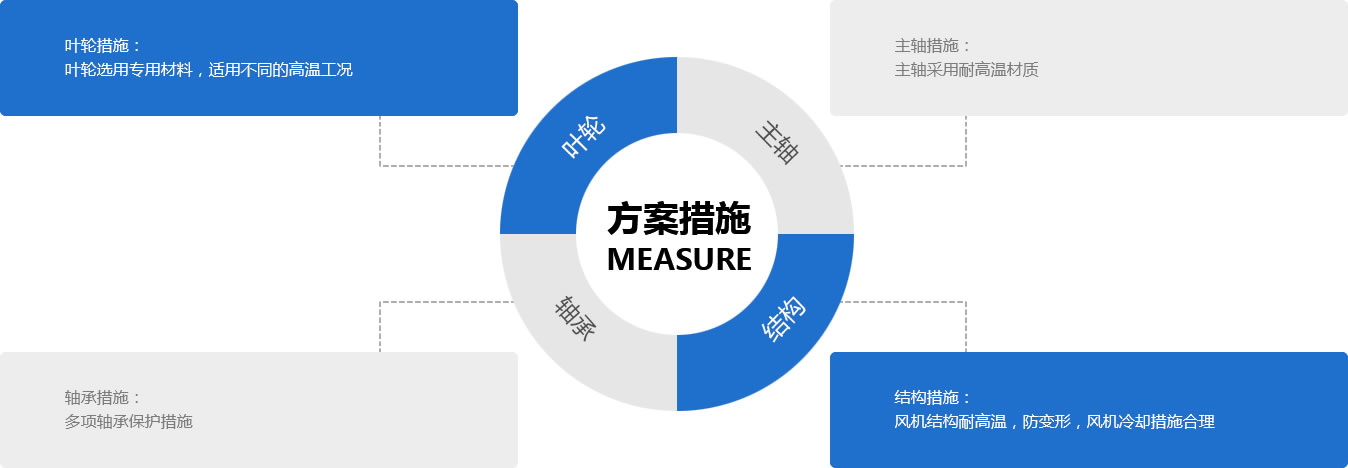

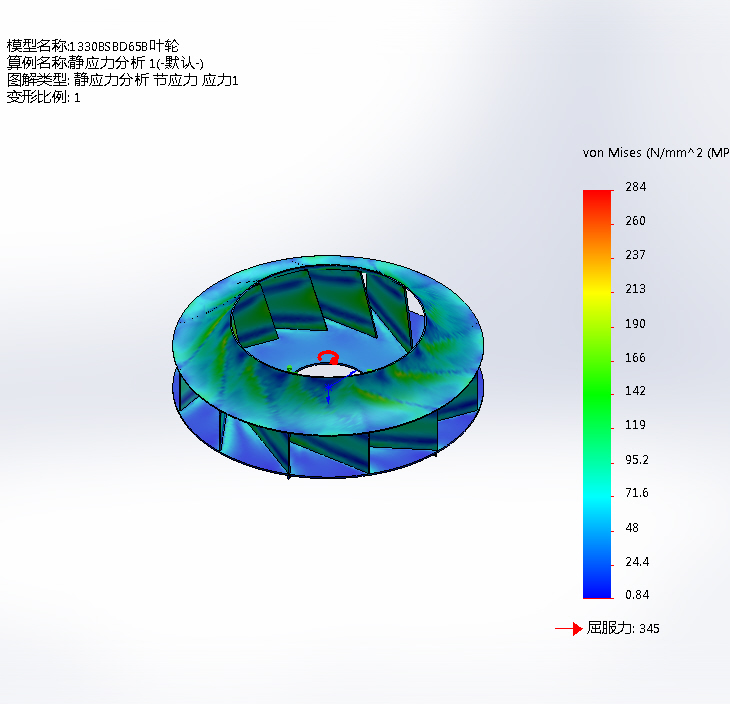

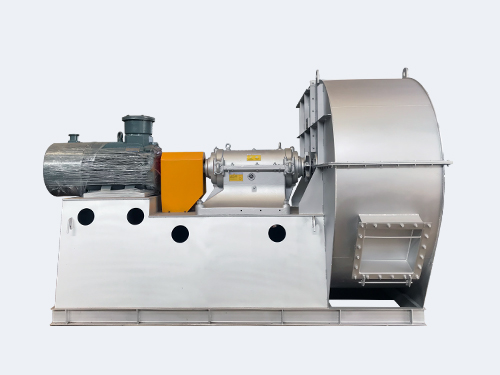

Under the temperature environment of more than 350°, the strength of most materials will be greatly reduced, and in the face of special process requirements such as cement plants, steel plants, chemical plants, etc., the fans need to work in a high temperature environment of more than 350°, which requires The high temperature fan has good heat resistance and high temperature wind resistance.

Specific speedSimo Blower can design and manufacture industrial centrifugal fans for various purposes according to customer needs

We can design individually according to customer's special needs

Fan performance parameters

Design according to the provided parameters

This series of

products

Common models can be designed as high temperature structures as required

Application

Environment

High temperature furnace, high temperature gas delivery, flue gas circulation, etc.

Our fan has a more efficient and energy-saving operation effect

The company has now developed into a professional production enterprise integrating R&D, manufacturing, performance testing,

installation and commissioning one-stop services

Transmission mode of high temperature centrifugal fan

The transmission modes of high temperature centrifugal fans currently include motor direct drive (A type), belt drive (C type) and coupling transmis...

How high is the high temperature fan?

The transmission modes of high temperature centrifugal fans currently include motor direct drive (A type), belt drive (C type) and coupling transmis...

High temperature fan cooling method

The cooling methods of the high temperature fan spindle are mainly divided into two types: air-cooled and water-cooled. Air-cooled construction is a...

Common faults and solutions of high temperature centrifugal fans

Centrifugal fans are not unfamiliar to everyone. As the name suggests, high-temperature centrifugal fans are centrifugal fans that can be used in hi...

Please fill in the information, we will arrange someone to serve you as soon as possible

If you are interested in our products or services, welcome to inquire!

Hotline:0373-5827689 13603935651

Hotline:0373-5827689 / 13603935651

Email:xmfjyxb@163.com

Address:China ● No. 343, Xima Avenue, Fengquan District, Xinxiang City, Henan Province

Copyright © 2021-2022 Xinxiang Simo Blower Co., Ltd. Henan ICP No. 19025136-2 SITEXML