-

NEWS CENTER

NEWS CENTER -

Contact Us

Contact Us

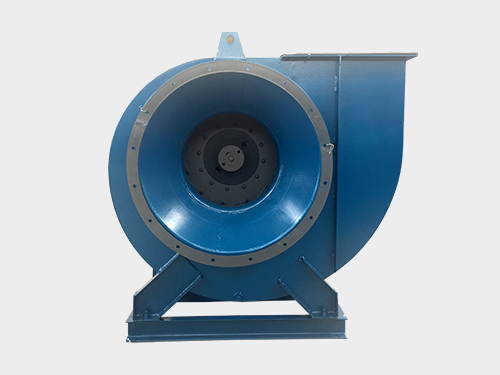

Model: Y5-47 boiler induced draft fan

Machine No.: 4#~24#

Air volume: 590-560735m3/h

Wind pressure: 684-9887Pa

Power: 3kw-710kW

Uses: Industrial boilers with various coal qualities and equipped with smoke and dust removal devices (1~20 tons/hour)

Form: The fan is made into single suction, and the machine numbers are №4C, 5C, 6C, 8C, 9C, 4D, 5D, 10D, 11D, 12D, 12.4D, 14D, 16.5D, 18D, 20D, 22D, 24D in total ten Seven total. When the above models cannot meet your needs, we have the ability to design according to your needs.

working conditions

The 5-47 series centrifugal draft fan is a boiler induced draft fan with a total pressure efficiency of 90.5% specially designed for industrial boilers with various coal qualities and equipped with smoke and dust removal devices (1~20 tons/hour). It can also be used to transport various common gases and hard materials in industrial production, and is suitable for various harsh working conditions such as high temperature, wear and corrosion.

Application scenarios

It is used for medium transportation in power generation projects such as hazardous waste heat boilers, carbon waste heat boilers, chemical waste heat boilers, coking waste heat boilers, sintering machine waste heat boilers, glass kiln waste heat boilers, etc. It has wear resistance, high efficiency, low noise, and stable gas flow. Good performance, wide high-efficiency area, compact structure, convenient maintenance, etc.。

product structure

Fan Features

●It can output higher outlet pressure and provide more gas flow at the same time with lower noise. It can work stably at higher medium temperature.

●The pressure and flow of the fan can be flexibly adjusted during operation by using the regulating door. It can also be equipped with a variable frequency motor to adjust the pressure and flow of the fan by changing the speed.

●Bearing cooling method, choose low-cost water cooling method or oil cooling method with better heat dissipation performance according to the gas temperature and the conditions of the use environment. For extremely high temperature operating conditions, an electronic cooler can also be installed to protect the reliable operation of the fan system.

●Material of impeller and main shaft, we will choose to use high-strength carbon steel, low-alloy steel, high-temperature-resistant alloy steel, high-temperature-resistant high-strength alloy steel according to different working conditions, temperature and working speed, so that the impeller and main shaft can withstand high temperature Reliable strength is still maintained.

●For dusty gas, we can meet various working conditions from a small amount of dust to a very large amount of dust. After special treatment, the surface hardness of the blade can reach HRC60~70, which can prolong the life of the impeller by more than 3 times.

●The bearing box has reserved installation positions for temperature and vibration sensors, which can easily install the fan operation monitoring device.

●The welding seam of the impeller and the main shaft are ultrasonic flaw detection to ensure that there are no welding defects and material defects, and the strength is guaranteed.

●After the production is completed, the operation is tested and the vibration value is detected, and the operation is reliable.

●There are a variety of optional accessories to choose from.

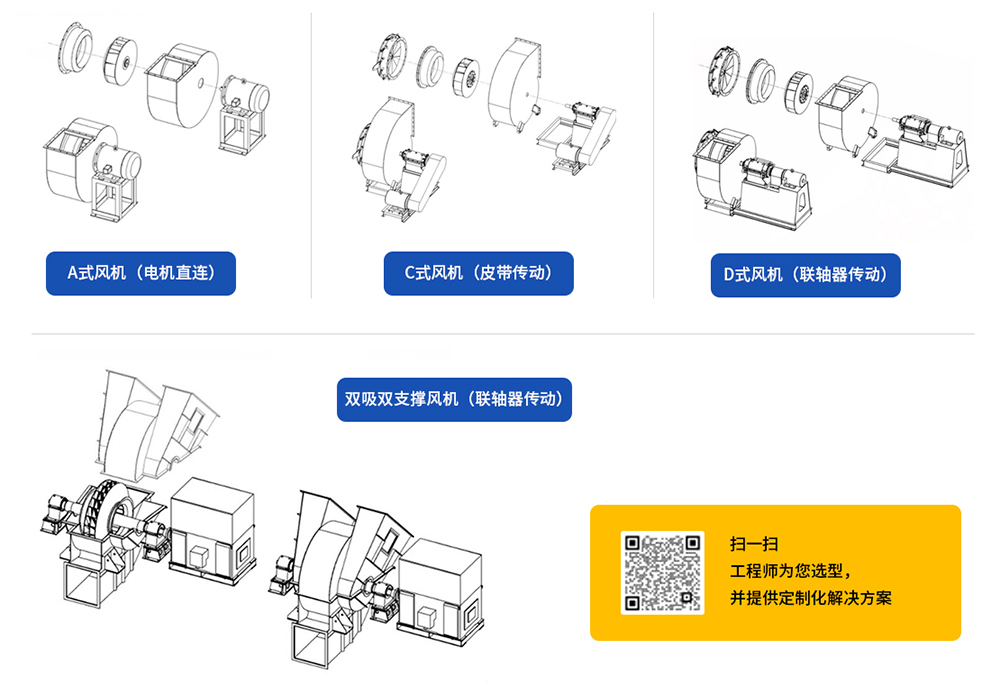

● Fan form: click direct connection, belt drive, coupling drive;

Fan configuration

● Motor brands: Simma Motor, Lu'an Motor, Wannan Motor, ABB, Siemens and other well-known brands at home and abroad (can be specified);

● Impeller: high-quality carbon steel, stainless steel, rubber lining, wear-resistant layer or wear-resistant lining plate, ceramic patch (can be specified);

● Bearing: SKF, FAG, Wafangdian, NSK (can be specified);

● Spindle: high-strength carbon steel, combined with steel

●Bearing seat: cast iron

●Optional configuration: ※Integral bracket; ※Protective cover; ※Muffler; ※Inlet and export compensator; ※Hydraulic coupling;※Motor rain cover;※Temperature sensor;※Vibration sensor;※Soft start device;※Inverter;

Hotline:0373-5827689 / 13603935651

Email:xmfjyxb@163.com

Address:China ● No. 343, Xima Avenue, Fengquan District, Xinxiang City, Henan Province

Copyright © 2021-2022 Xinxiang Simo Blower Co., Ltd. Henan ICP No. 19025136-2 SITEXML