-

NEWS CENTER

NEWS CENTER -

Contact Us

Contact Us

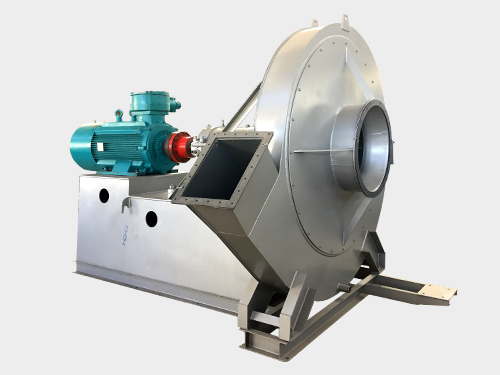

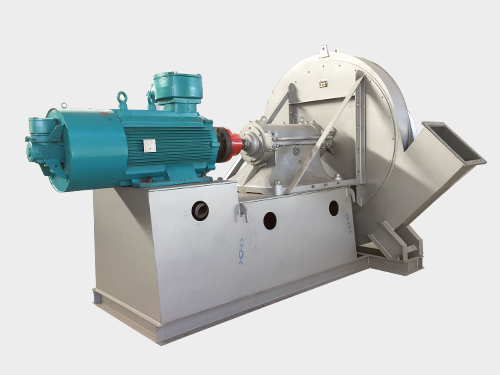

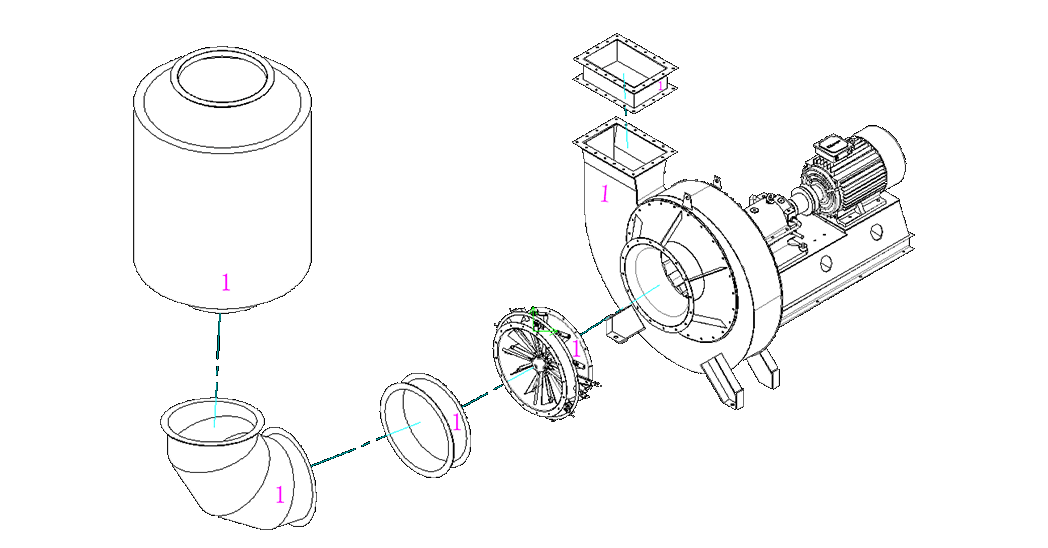

Model: 9-19 type high pressure centrifugal fan

Machine No.: 4#~20#

Air volume: 273~81858m3/h

Wind pressure: 348~10282Pa

Power: 2.2~400kW

Uses: used in high-pressure forced ventilation occasions such as forging furnaces, boilers, etc.

Form: single-suction type, can be made into two types of left-hand and right-hand. There are fifteen types of 14D, 16D, 18D and 20D. When the above machine numbers cannot meet your needs, we have the ability to design them according to your needs.

working conditions

The 9-19 type centrifugal fan can be used for general ventilation and indoor ventilation in general factories and large buildings. Can be used as both input gas and output gas. The gas to be transported should be air and other gases that are not spontaneously combustible, harmless to human body, and non-corrosive to steel materials. The gas does not contain viscous substances, the dust and hard particles contained are not more than 150mg/m3, and the gas temperature should not exceed 80 °C.

Application scenarios

Forced ventilation, rapid drying, rapid cooling and heat dissipation, cooling of grate coolers in cement production lines, circulating fluidized bed systems, air purification and industrial waste gas treatment, flue gas desulfurization, ventilation of blast mill systems for industrial boilers or incinerators, Scenarios such as industrial waste heat recovery devices, blasting of smelting furnaces and casting furnaces, combustion support of blast furnaces, coal injection of blast furnaces, pressurized transportation of gas, and pressurized or decompressed sealing of industrial equipment.

product structure

Fan Features

●It can output high outlet pressure, and can work under high medium temperature, suitable for any industrial occasions that need to transport high pressure & high temperature gas.

●In the case of using the integral bracket, the installation is very simple and basically does not require the support of technical personnel.

●The bearing box has reserved installation positions for temperature and vibration sensors, which can easily install the fan operation monitoring device.

●When the airflow resistance increases, the motor load will be automatically reduced, and the motor will not be burned.

●Customized design according to customer performance requirements, and optimized by CFD technology, the energy consumption is lower than similar models.

●The components are closely matched with each other, and the sealing performance is good to ensure that the output pressure will not decrease.

●The impeller is corrected by high standard dynamic balance to ensure the stable operation of the fan.

●After the production is completed, the operation is tested and the vibration value is detected, and the operation is reliable.

●There are a variety of optional accessories to choose from.

● Fan form: click direct connection, belt drive, coupling drive;

● Motor brands: Simma Motor, Lu'an Motor, Wannan Motor, ABB, Siemens and other well-known brands at home and abroad (can be specified);

● Impeller: high-quality carbon steel, stainless steel, rubber lining, wear-resistant layer or wear-resistant lining plate, ceramic patch (can be specified);

● Bearing: SKF, FAG, Wafangdian, NSK (can be specified);

● Spindle: high-strength carbon steel, combined with steel

●Bearing seat: cast iron

●Optional configuration: ※Integral bracket; ※Protective cover; ※Silencer; ;※Motor rain cover;※Temperature sensor;※Vibration sensor;※Inverter;

Hotline:0373-5827689 / 13603935651

Email:xmfjyxb@163.com

Address:China ● No. 343, Xima Avenue, Fengquan District, Xinxiang City, Henan Province

Copyright © 2021-2022 Xinxiang Simo Blower Co., Ltd. Henan ICP No. 19025136-2 SITEXML