-

NEWS CENTER

NEWS CENTER -

Contact Us

Contact Us

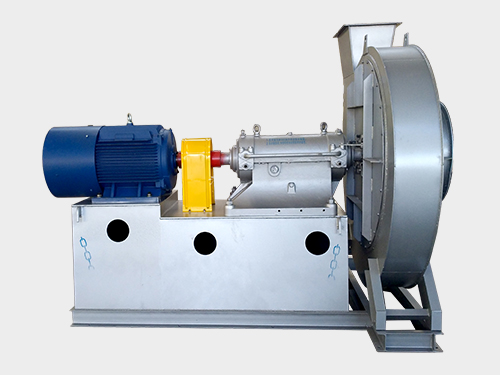

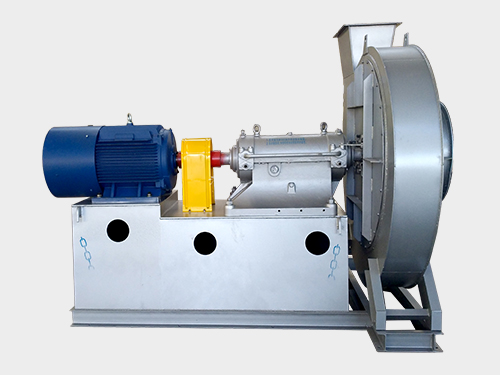

Model: 9-26 high pressure centrifugal fan

Machine No.: 4#~20#

Air volume: 2473~159172m3/h

Wind pressure: 3876~10815Pa

Power: 2.2~710kW

Uses: used in high-pressure forced ventilation occasions such as forging furnaces, boilers, etc.

Form: single-suction type, can be made into two types of left-hand and right-hand. 14D, 16D, 18D, 20D, a total of 15 machine numbers, when the above machine numbers can not meet your needs, we have the ability to design according to your needs.

working conditions

Type 9-26 high-pressure centrifugal fan is generally used for forging furnaces and high-pressure forced ventilation, and can be widely used for conveying materials, conveying air, and non-corrosive, non-spontaneous, and non-viscous gases. The temperature of the medium is generally not more than 80℃, and the dust and hard particles contained in the medium are not more than 150mg/m³. For flammable and explosive gas delivery, the impeller can be made of aluminum alloy to prevent sparks during operation. The motor is an explosion-proof motor, and its performance parameters are the same as those of ordinary motors.

Application scenarios

Forced ventilation, rapid drying, rapid cooling and heat dissipation, grate cooler cooling in cement production lines, circulating fluidized bed systems, air purification and industrial waste gas treatment, flue gas desulfurization, blasting of industrial boilers or incinerators, ventilation of large mill systems , industrial waste heat recovery device, blasting of smelting furnace and casting furnace, combustion support of blast furnace, coal injection of blast furnace, pressurized transportation of gas, pressurized or decompressed sealing of industrial equipment, etc.

Fan Features

●It can output higher gas pressure, and can provide more gas flow at the same time, with lower noise.

●In the case of using the integral bracket, the installation is very simple and basically does not require the support of technical personnel.

●The motor shaft is elastically connected with the transmission shaft, so there is no need to frequently tension the belt or replace the belt, and the maintenance workload is small.

●The fan system with impeller diameter below 1400mm running at room temperature does not need to be equipped with additional bearing cooling device, which reduces the user's investment and maintenance workload.

●When the airflow resistance increases, the motor load will be automatically reduced, and the motor will not be burned.

● Made of high-quality carbon steel, stainless steel or other metal materials can also be used according to user requirements.

●After the production is completed, the operation is tested and the vibration value is detected, and the operation is reliable.

Fan configuration

● Fan form: direct motor connection, belt drive, coupling drive;

● Motor brands: Simma Motor, Lu'an Motor, Wannan Motor, ABB, Siemens and other well-known brands at home and abroad (can be specified);

● Impeller: high-quality carbon steel, stainless steel, rubber lining, wear-resistant layer or wear-resistant lining plate, ceramic patch (can be specified);

● Bearing: SKF, FAG, Wafangdian, NSK (can be specified);

● Spindle: high-strength carbon steel, combined with steel (can be specified);

●Bearing seat: cast iron

●Optional configuration: ※Integral bracket; ※Protective cover; ※Silencer; ※Inlet and export compensator; ※Hydraulic coupling;※Motor rain cover;※Temperature sensor;※Vibration sensor;※Inverter;

Hotline:0373-5827689 / 13603935651

Email:xmfjyxb@163.com

Address:China ● No. 343, Xima Avenue, Fengquan District, Xinxiang City, Henan Province

Copyright © 2021-2022 Xinxiang Simo Blower Co., Ltd. Henan ICP No. 19025136-2 SITEXML