-

NEWS CENTER

NEWS CENTER -

Contact Us

Contact Us

Pelletizing is one of the two common processes for extracting iron ore raw materials in the iron and steel smelting industry. The main equipment for pelletizing production includes dryers, high-pressure rail grinders, high-strength mixers, disc pelletizers, and chain grate machines. , rotary kiln, ring cooler, electrostatic precipitator, circulating fan, etc. Our company can provide you with a complete set of equipment for pelletizing process fans. Welcome to visit the factory for inspection and exchange.

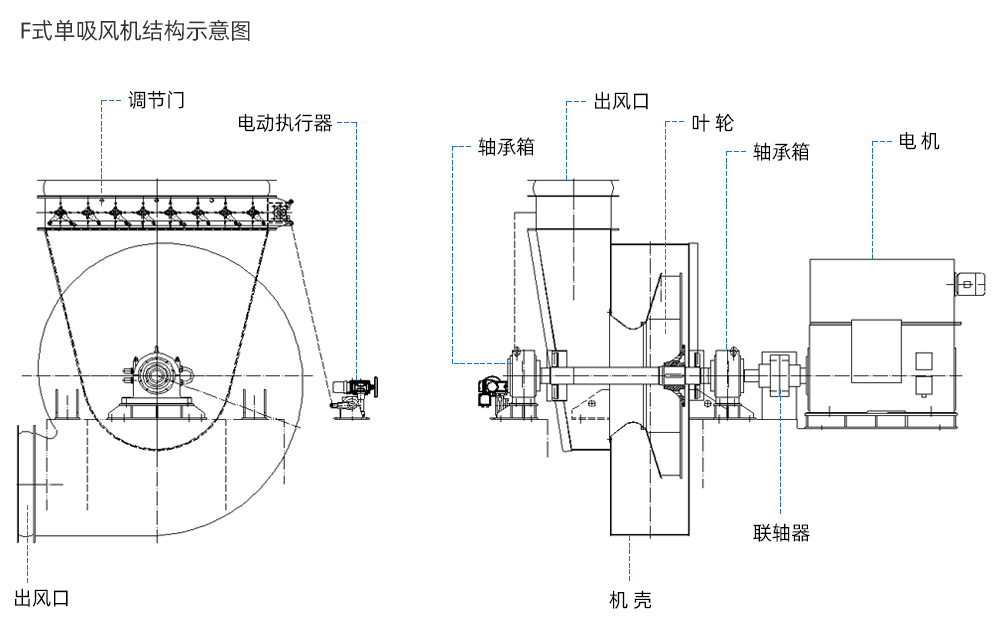

Centrifugal Fan

Combustion fan

Drying drum (exhaust) fan

Main exhaust fan

Heat recovery fan

Ring cooling fan

Pelletizing Room

roasting section

roasting section

roasting section

roasting section

roasting section

Simo Blower can design and manufacture industrial centrifugal fans for various purposes according to customer needs

Simo Blower is a professional production enterprise integrating R&D, manufacturing, performance testing, installation and commissioning one-stop services

Our products are reliable in quality and stable in performance, and have won unanimous praise from cooperative customers

Sintering machine fans and cooling fans in large steel mills; induced draft fans for hot blast furnaces; high temperature and wear-resistant process fans for waste heat power generation, coke dry quenching and pelletizing

Hotline:0373-5827689 / 13603935651

Email:xmfjyxb@163.com

Address:China ● No. 343, Xima Avenue, Fengquan District, Xinxiang City, Henan Province

Copyright © 2021-2022 Xinxiang Simo Blower Co., Ltd. Henan ICP No. 19025136-2 SITEXML